Review of Mold before Injection Making

The review before the mold orders are made, so that the problem points are found and eliminated before the mold is made.

01

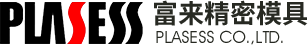

DFM made

Mold production before the implementation of DFM review, review of the mold gate, structure, dividing line, etc. And discuss with the customer to reach an agreement.

02

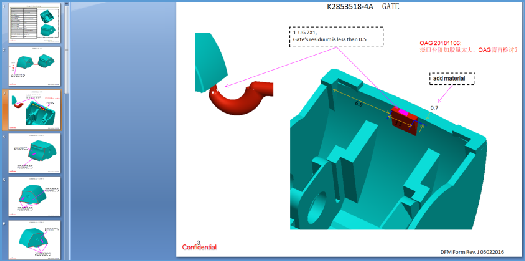

CAE Analysis

DFM review when the mold flow analysis, analysis of possible problems, in advance of countermeasures to improve. Development of easy-to-use molds for mass production plants.

03

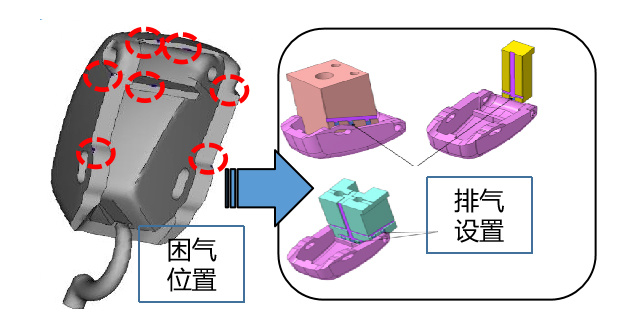

Not open

The non-matching content of the past mold is stored in the management system developed by the company. Before the development of the new mold, the expected problems are improved.

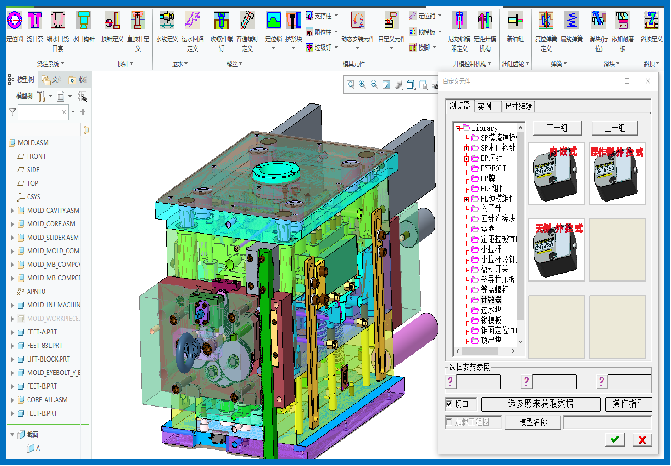

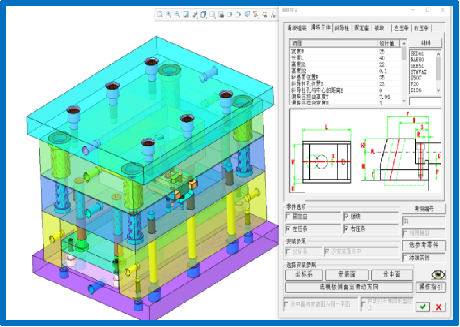

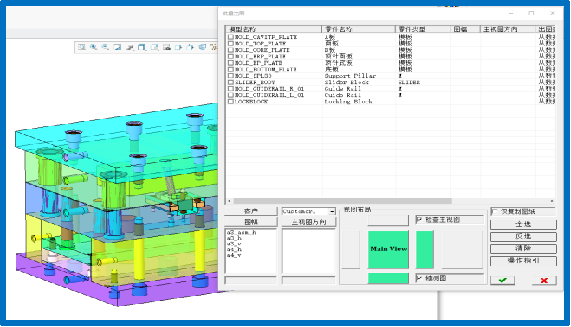

Mold full 3D design and automatic design

Die design standards and automation to avoid human error and improve efficiency.

01

① Use 3D design plug-in software. According to customer standards into parts of the database, the design of direct calls, fast and accurate. ② The main parameters are input during design to generate parts or components, and the parameters can be modified at will to regenerate component specifications, and features such as mounting holes and grooves can be automatically generated at the installation site.

02

At the same time, the full 3D CREO(13 sets) platform, Creda(7 sets) plug-in design, self-built standard parts library, to meet the group standards and customer standards. Can very quickly complete the slider assembly, EP and other parts of the call and adjustment.

03

Automatic BOM generation, The mold BOM is automatically exported based on the part parameters. Automatic design increases design efficiency by more than 35%, And effectively reduce the incidence of adverse.

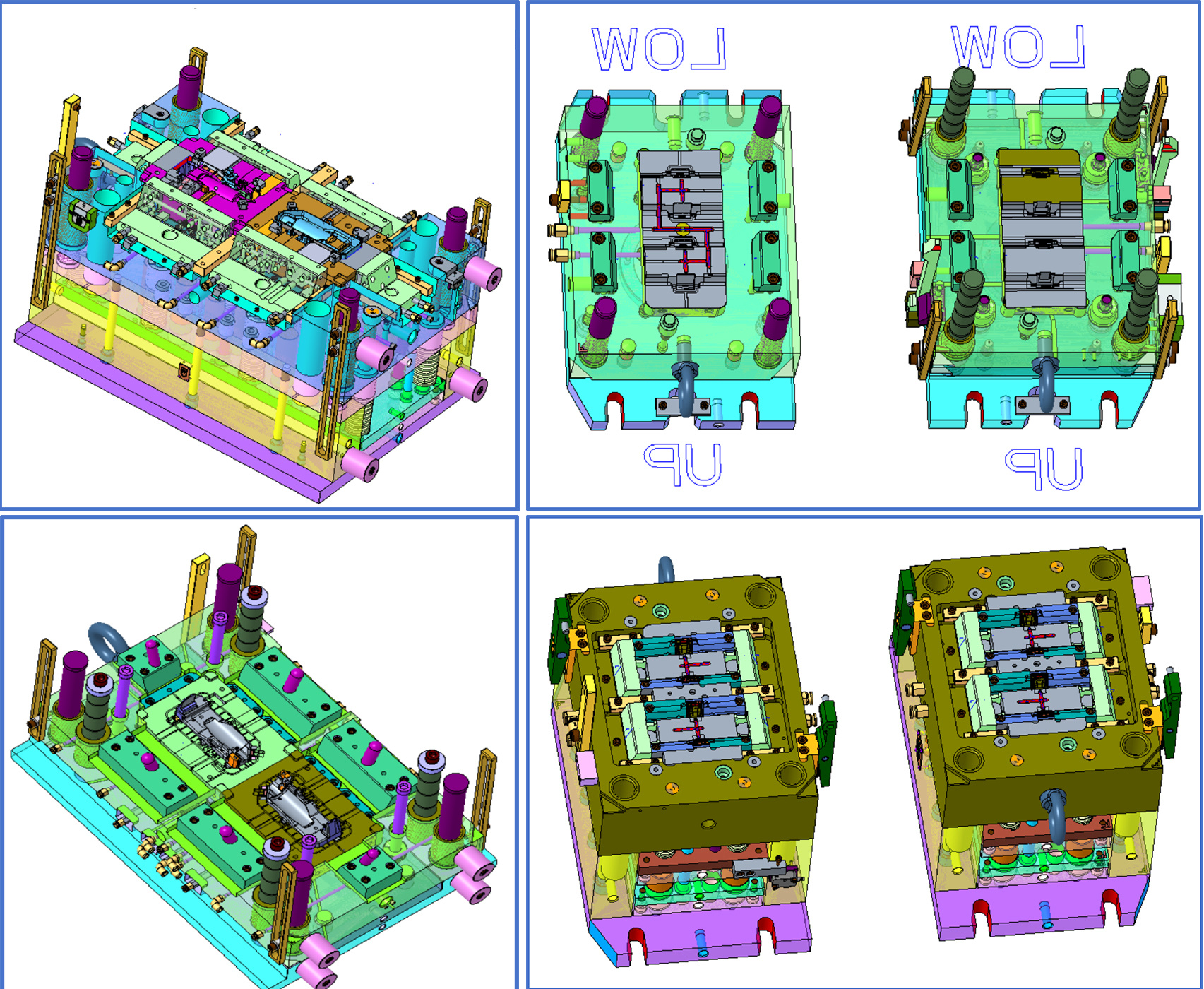

04

Design mold example display. The product of this mold is an automotive carbon canister filter holder. (Left 1 Left 2) The product of this mold is a two-color button for car central control. (Right 1 Right 2)

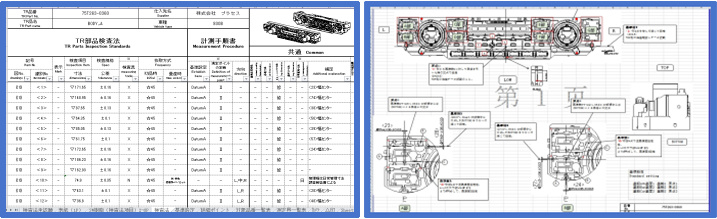

Unified measurement method for mold development process and mass production plant

High-precision measuring equipment and management, the real reaction to the actual results of the product.

01

Before type TO, review and make a measurement benchmark with the customer, and obtain the customer's acceptance. The purpose is to unify the detailed measurement points and measurement methods of each size with the customer. Avoid differences in mass production measurement methods when passing tubes.

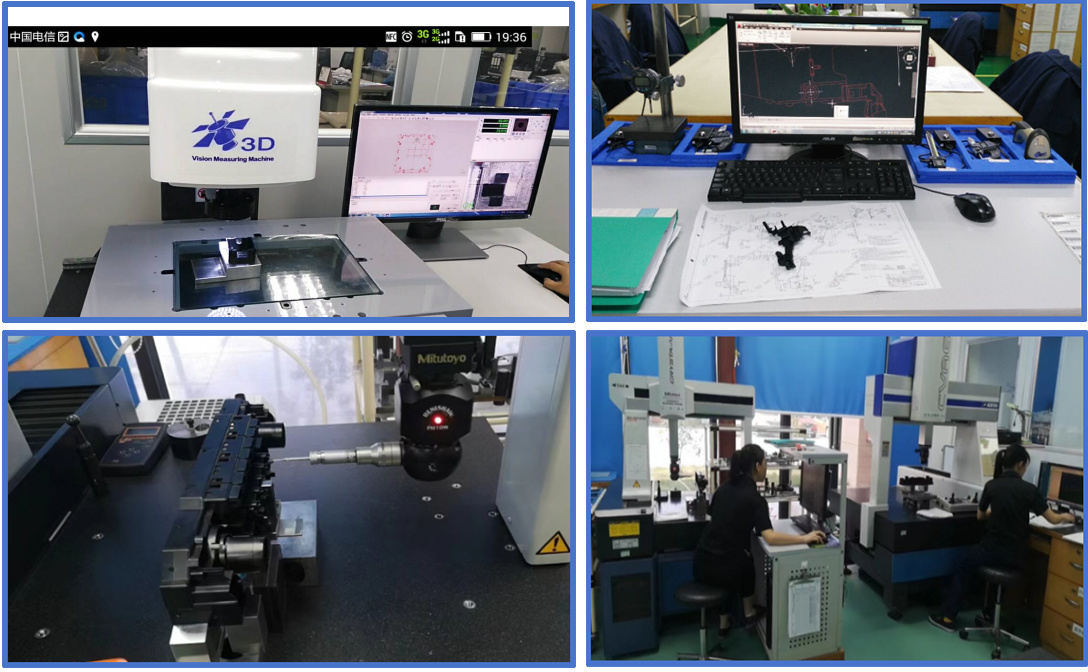

02

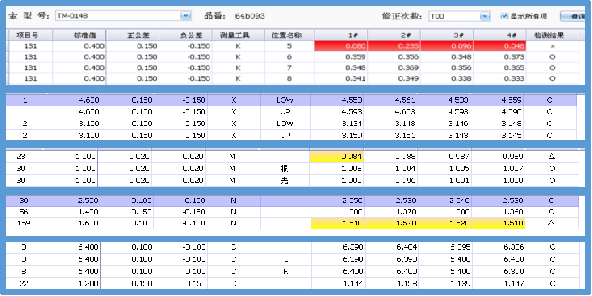

It has automatic secondary and tertiary equipment, caliper, micrometer and altimeter data automatic force assembly. It can realize automatic measurement of the program and ensure the unity of each measurement position.

03

3 yuan, 2 yuan, caliper, micrometer, altimeter and other measurement data automatic import system. Realize automatic data output and judgment. Saves manual input while avoiding human error.

04

Commonly used gauge standardized placement, reducing the measuring tool to find time, high efficiency.

In accordance with our company motto, "Planning is implementation," we have built a relationship of trust with our customers since the establishment of Mori Die & Mold in 1977, based on careful planning and prompt action. "It is our desire to help our customers succeed, and it is also our company's success.

Fulai Precision Mold (Zhongshan) Co., Ltd.

Address: 1/3, 2/F, Building E, No. 21 Yanjiang Dongsan Road, Torch Development Zone, Zhongshan, Guangdong, China

Tel:0760-85314317

18925321803 ( Mr. Li )

Copyright © Fulai Precision Mold (Zhongshan) Co., Ltd. Business License